It includes five essays by experts who provide an overview of where the innovators’ work is heading. Two especially interesting pieces offer descriptions of and predictions for computers that replace electric current with light and building materials with decision-making abilities.

Our conventional transistors are going to eventually hit the limit regarding the number of circuits that can be packed into their microstructures. To continue improvement, alternatives are being developed that include quantum computers, optoelectronic components made from two-dimensional materials, and analog circuitry. One of the innovators on MIT’s list, Xu Zhang of Carnegie Mellon University, has developed a semiconductor that’s just atoms thick—making it practically two-dimensional. Zhang explains, “By transforming semiconductors from 3D to 2D, it is possible to truly push computing technologies to the ultimate atomic limit and enable future ubiquitous computing and ambient intelligence.”

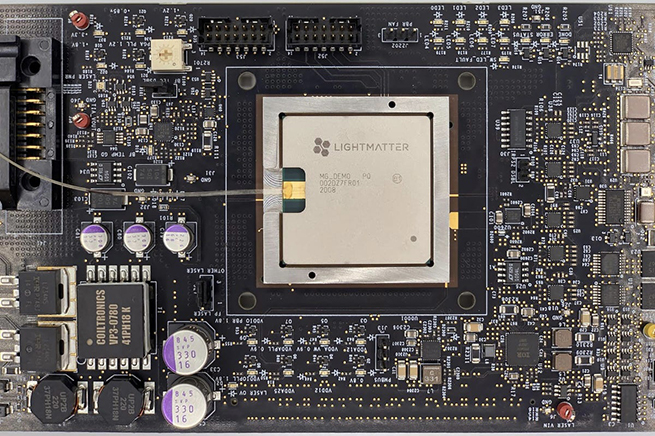

Optical computing was an early idea that was abandoned in favor of binary electronic circuits. Now, the interest in making computers that use light instead of currents, photons instead of electrons, is moving forward again. Prineha Narang, professor in physical sciences at University of California, Los Angeles, claims, “This is already happening: silicon photonic chips are providing high energy efficiency and are helping overcome the slowdown issues in traditional GPU architectures. They can reduce the time needed to train deep-learning models, enabling the next generation of advanced AI…. In the long term, such photonic circuits could help us approach or perhaps even surpass widely accepted limits in computing.”

MATERIALS

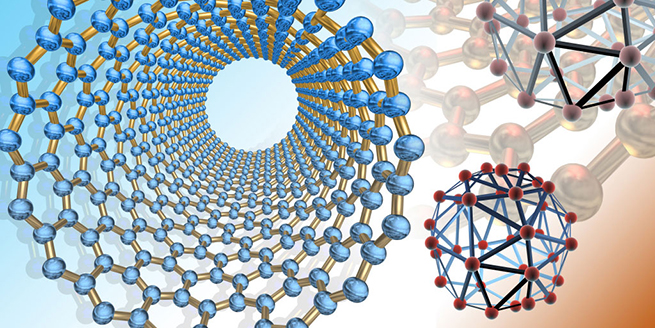

The bland-sounding field of “materials science” has an equally unremarkable-sounding definition: It is the interdisciplinary field that studies the discovery and design of new materials. But take just a few steps inside the door in a materials lab where the work involves mimicry of natural patterns built into atomic or nanoscale projects, and you’ll discover one of the most exotic of modern sciences. Before we get to where materials science may take us regarding computing, perhaps we should start with a general idea of what engineering and design at a submicroscopic level is.

Stephanie Tompkins, one of the lead materials scientists at Defense Advanced Research Projects Agency (DARPA), was asked to describe her work in a short video. She opens with a question about the future in 2045. “Will we be able to recognize materials that make up the world around us?” The materials to build homes, cars, and airplanes then “will have properties that we, right now, instinctively believe are completely impossible.”

Today, Tompkins continues, we try to think of ways to use materials we have at hand, and we’re stuck with the constraints nature has given us. These include conditions like the stronger a material is, the more likely it is to be heavy and inflexible. She asks, what if you were able to make panels of construction material that were as strong as granite but as light as Styrofoam? To accomplish this, she explains, you would probably have to go back to the molecular or even atomic level and build in a design structure that provides strength and flexibility in a lightweight form. For the last 60 years, material scientists have been trying to figure out how to build at that elemental level and then work toward materials we can see and touch. Tompkins reports we now can move from a molecular scale to things that are nanoscale particles, and it will eventually move up to things we can see and are large-scale particles that she proposes are going to make up our future.

One of MIT’s 35 awardees working in materials, Carlos Portela, explains that 3D nanomaterials could flip assumptions like glass can break, ceramic is brittle, and metal is heavy on their head. “Ceramics do not have to be brittle, a material’s color could change on demand, and a metallic material could be as light as a feather—all due to engineered 3D nanostructures.” Julia Greer, who wrote the essay on materials for the Review, adds, “Such materials have so far been made only in microscopic amounts in the lab, but Portela has developed a process that allows him to create 3D nanomaterials that you can hold in your hand. Such materials could help address a variety of engineering challenges, he says, since they have properties that no existing material could ever attain.”

Greer is a materials scientist at the California Institute of Technology and has been working in the field for 24 years. Materials science as a field in itself has only been in development for 50 to 60 years. Greer was a previous Innovative 35 winner in 2008, and her introductory essay about materials research and computers is eye-opening. After describing the hierarchical patterns in nature that repeat all the way down to the molecular level, inducing properties that strengthen our bones without making them heavy and that color butterfly wings, she asks, “What if we could engineer such properties directly into manufactured materials? This could remove the need for complicated manufacturing processes to create devices like stents, microprocessors, and batteries. And eventually, we may even be able to program some degree of intelligence directly into the materials that make up such devices, which could make new features and functionality possible.” She then predicts that architected materials—that is, substances built up from the nanoscale—could have useful properties that will eventually replace conventional materials. Her research at Caltech has reached the stage where her teams can make new materials from components that are “just a little larger than 100 atoms to several millimeters in size.”

Not only could this create an entirely new universe of materials “decoupled from properties that have been historically linked together (strong and heavy for instance),” but Greer also thinks architected materials “can evolve in space and time in response to a pre-programmed trigger. They can morph into different shapes to respond or adapt to a new environment or stimulus.”

What that might mean for computers could be significant. One example Greer mentions is that “some architected materials have already incorporated new kinds of logic gates that respond to either mechanical or chemical stimuli.” Another area where she sees great potential “involves using machine learning to predict new architectures for materials that can emulate computationally trained neural networks using light instead of digital input. Eventually, artificial networks could be integrated into architected physical materials to make decisions, eliminating the need to first convert the input into digital signals and then process them in computers. This means materials themselves could someday be made to recognize faces or objects, process language, and classify text or numbers.” Sounds something like Xu Zhang’s vision for ambient intelligence.

There’s a long way to go yet, Greer admits—first there must be computational models of the additive manufacturing process to make these materials, then the leap to turn the prototypes into technology, and then the manufacture of the materials at scale. Nevertheless, she concludes, “I look forward to the day when we can create architected materials and devices imbued with the ability to make decisions on their own.”

The use of light in computer processing is well under way, and with networks wired with fiber that transmits light, much more can be expected. Materials science, on the other hand, is only at the beginning of what may become an upheaval unlike any we have experienced coming from technology.