This is the third time WARR Hyperloop won the competition. In August 2017, they won when their pod reached the 201 mph (324 km/h) mark, and in January 2017 their winning pod accelerated to 58 mph (93 km/h) in the test-track tunnel.

This latest competition featured 29 university teams and was hosted by SpaceX and Elon Musk at the company’s Hawthorne, Calif., headquarters. The new speed record moves the hyperloop pod closer to the world’s fastest train—Japan’s experimental Maglev Train LO Series, which has sailed above ground at 375 mph.

The three teams that made it to the finals on July 22 were all from Europe. Along with the WARR pod, there were the Delft Hyperloop from Delft University of Technology and EPFLoop from Lausanne, Switzerland.

SpaceX isn’t building hyperloop trains, but company owner Musk has provided the 1.25 km. partial-vacuum test track adjacent to company headquarters. Musk explains, “SpaceX is revolutionizing terrestrial transportation through its Hyperloop services. The company currently provides these services to innovators and universities across the world interested in high-speed transportation technology and solutions.”

The SpaceX Test Tunnel/Photo by Okras-Own work, CC BY-SA 4.0

HYPERSPEED TRANSPORT

The pods in this competition represent work toward a final proof of concept stage for a hyperloop system—with an ultimate goal of speeds exceeding 700 mph. One original hyperloop design derives from a white paper done by Musk. In the paper, he describes a combination of forces operating within the tube. The capsule, or pod, is pulled along on a rail by magnetic attraction provided by electric pulse generators every 70 or so miles. Air pressure, which creates resistance, is kept at a minimum by maintaining a near vacuum within the tube. Additionally, a powerful fan at the front of the pod will pull in the oncoming air, redirect it to two onboard compressors, and then eject it backwards away from the capsule.

The WARR capsule/Photo by WARR Hyperloop Facebook

The capsule floats through the tunnel, levitated by the air pressure coming off the exterior of the capsule. Flat plates surround the capsule and evenly push back against the air displaced by the capsule’s forward movement. It floats off the rail and away from the steel walls of the tunnel, which can be located above or below ground.

The original vision calls for six to eight passengers in each capsule and three capsules per “train.”

COMPETITION RULES

The published requirements for the Hyperloop competition reflect the scaled down reality of the current experimental pods:

- “The weight should be less than 3,306 lbs. (1,500 kg).

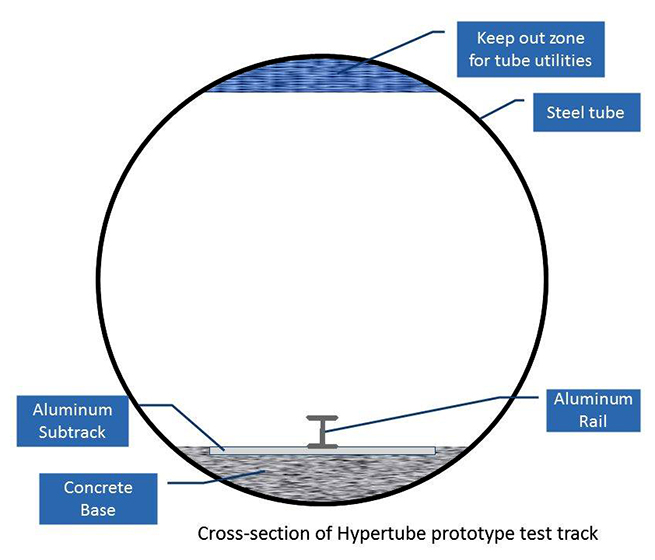

- Pods shall fit within the cross-section provided within the SpaceX Hyperloop Test Track Specification. Pod minimum length is 5 feet. Pod maximum length is 24 feet.

- Service Propulsion System: The Pod shall be moveable at low speeds when not in operation, which may be accomplished by physically pushing it (wheels), physically lifting it (even with a dolly), or remotely controlling it.

- Dummy Passenger: While not a hard requirement, it is suggested that the Pod accommodate at least 1 dummy. The dummy does not have to be given a life support system, but should be physically in the Pod in a reasonable orientation for the duration of the test. The dimensions of the dummy are up to the entrants, who should be prepared to explain their choice of size.

- See separate Test Track Specification for detailed safety requirements.” (The safety requirements covered stopping systems and plans to handle accidental malfunctions during the test.)

A secondary competition tested levitation systems on a shorter 150-foot track. The pods were required to levitate over the course on a complete down and back cycle on the track.

Photo by N2e-Own work, CC BY-SA 4.0

The development of hyperloop technology is accelerating along with the pods, and new start-ups will be providing more resources between now and the next round of test trials. There still is quite a distance between this technology and the Maglev high-speed trains already in operation. But if the hyperloop crosses over into commercial operations, its flexibility of installation, above and below ground, and its reduced-maintenance frictionless operation will justify the effort being made by so many.