The term “Industry 4.0” came out of Germany about seven years ago as part of a German government initiative to help small and medium-sized manufacturing enterprises in Germany become market leaders in providing advanced manufacturing solutions and to excel in a global economic environment that’s undergoing a digital transformation.

As global interest in this initiative started to take hold, different names were created.

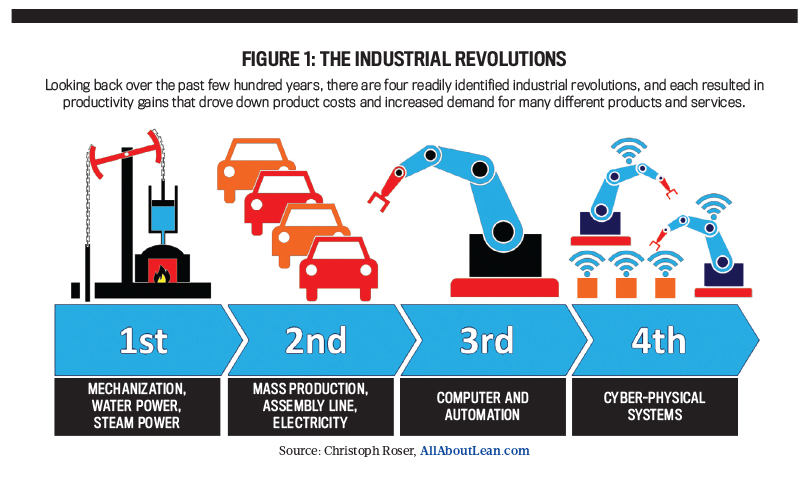

Here, in the United States, it might be called the Industrial Internet or smart manufacturing. I4.0 is the framework for the Made in China 2025 initiative; in Belgium, the term is Factories of the Future, while Sweden and the Netherlands call it Smart Industry. But even though this global movement has different names in different parts of the world, the underlying concepts are the same, and the coming of I4.0 is often referred to as the Fourth Industrial Revolution. (See Figure 1 for an overview of the industrial revolutions.)

AN I4.0 WORLD

When compared to previous industrial revolutions, the fourth is evolving at an exponential rather than linear pace. The Fourth Industrial Revolution is all about connectedness and the potential to reach a holy grail of economic mass customization of customer offerings. Within this revolution, we see a fusion of technologies that blurs the lines between the digital, physical, and biological domains, creating what are called cyber-physical systems. We have no historical precedent for the speed of current breakthroughs, and the breadth and depth of these changes can bring about the transformation of not only entire systems of production but also methods of management and governance. These changes will certainly impact the roles of accounting and finance professionals.

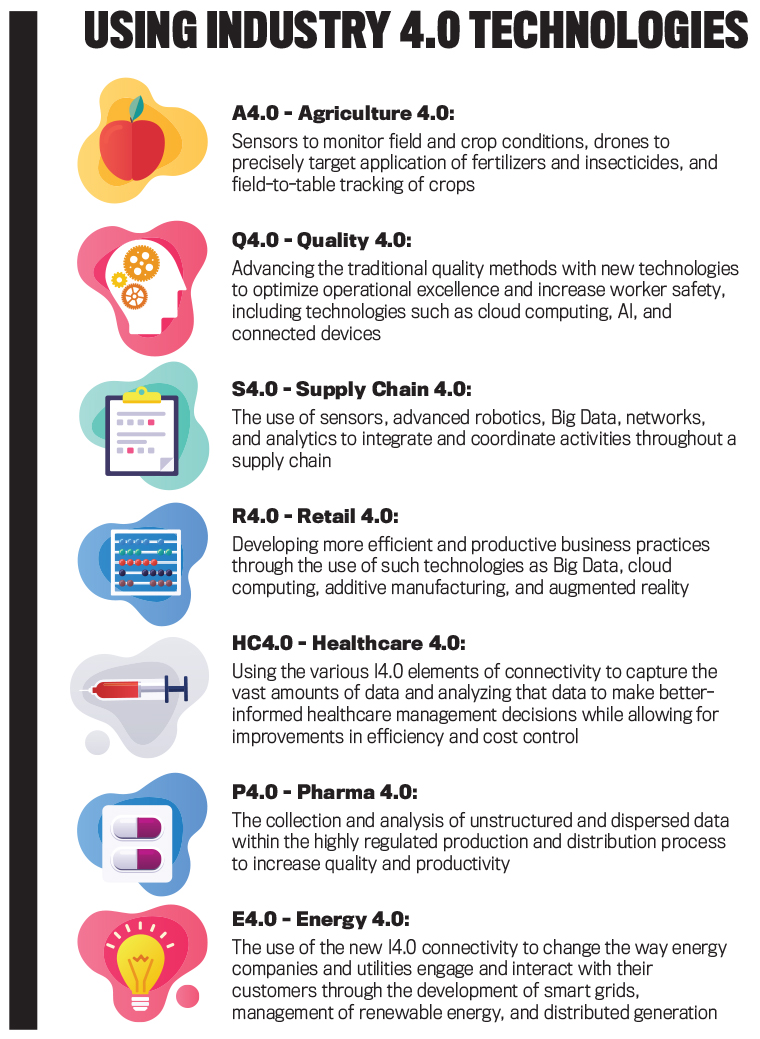

Also, and this is important, as seen in “Using Industry 4.0 Technologies,” I4.0 isn’t something that relates only to the manufacturing sector. You might say we will soon be living in an I4.0 world.

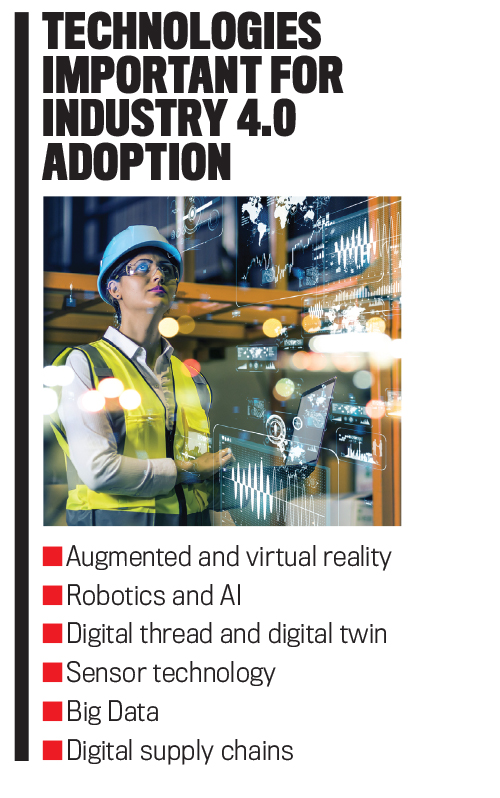

There is no doubt that advances in emerging and existing technologies, such as those listed in “Technologies Important for Industry 4.0 Adoption” (below), are necessary for I4.0 implementation. While knowledge of the technology is important and necessary, it isn’t sufficient for successful I4.0 implementation. I4.0 isn’t about adopting technology, it’s about capturing value, so much more needs to be considered when building a business case.

I4.0 isn’t coming; it’s here, and with it, financial planning and analysis (FP&A) professionals need a transformational mind-set. The internal financial management responsibilities of planning, budgeting, business reporting, decision analysis, and risk management will continue to be important, but transformation requires a clear understanding of what your business wants to look like tomorrow—and a precise sequenced road map to bring the strategic vision to life.

Concentrating on strategic results—where the company is headed—rather than individual technologies puts focus on driving enterprise value from the I4.0 investments. Maybe top-line growth is the priority, and investments in increased capacity to meet demand will be required. Maybe the business is focused on reducing costs to remain competitive in a market with tightening margins. Maybe the future of the organization rests on manufacturing flexibility or how to address new market pressures, such as the ability to meet increasing demands for customization. Along the way, you must beware of the hype surrounding the potential benefits that consultants extoll. The key is to develop a deep understanding of the value-creation opportunities that can come from innovation in your business and then make a case for strategically aligning resources and funding to capture that value.

An organization in transformation demands thoughtful investment in technology. Organizations need to prioritize innovation and strategic investment or risk losing competitive advantage. I4.0 technology investments require the same in-depth quantitative and qualitative analysis performed for all other potential major investments. It includes consideration of the short- and long-term costs and benefits—the net value-add to the business.

To evaluate an investment, one must understand the organization’s current strategic position and capabilities to help evaluate where capabilities gaps may exist. The understanding of strategic objectives is vital to ensure alignment during the subsequent discussions and decision making surrounding how to achieve those goals. Recognizing that the opportunities and issues will vary from organization to organization, we will review the opportunities and the surrounding issues Johnson & Johnson identified while going through the digital transformation of adopting I4.0 principles.

THE J&J JOURNEY

Johnson & Johnson (J&J) is the world’s largest and most broadly-based healthcare company, with sales of roughly $80 billion in 2019 across its Pharmaceuticals, Medical Devices, and Consumer Health segments. The foundation of J&J is the company’s credo, which spells out the values that guide its decision making. To serve its customers best, the company believes it must innovate and invest in the future and transform itself to influence the future of healthcare (www.jnj.com/credo).

Given J&J’s breath of business, each segment has different opportunities to employ I4.0 principles. “Industry 4.0 Opportunities at J&J” showcases a few examples of how J&J touches I4.0 in its various segments.

Healthcare and technology are connecting like never before, and we know that connectedness is the key to I4.0. The resulting potential impact to society can provide sweeping benefits from many perspectives, improving both quality of life and cost of delivery. We believe understanding healthcare’s dynamic landscape might shed some light into why I4.0 is gaining a foothold at J&J.

THE EVOLVING HEALTHCARE LANDSCAPE

Consolidation, partnership, and M&A continue to evolve the landscape of healthcare. Technology and digitalization are blurring the lines of what defines a traditional healthcare company vs. a healthcare company in the future. For example, Amazon’s 2018 acquisition of online pharmacy PillPack shows how a former online bookseller can transform into a contender in healthcare.

How did J&J decide to participate in the Fourth Industrial Revolution? The company began its journey into I4.0 by creating a Manufacturing for the Future (MFF) program. MFF’s goal is to enhance customer value through innovation and digitalization. Within this program, there are multiple pillars identified to drive value, including concepts like Smart Factory—leveraging AI, sensors, and 3D printing—where you can create custom SKUs or machine parts vs. producing a set of “stock” items.

Given that disruption is everywhere, J&J is driving toward an innovative approach with all stakeholders in order to enable success as laid out in the J&J credo. Take the application of I4.0 using medical technology, for example.

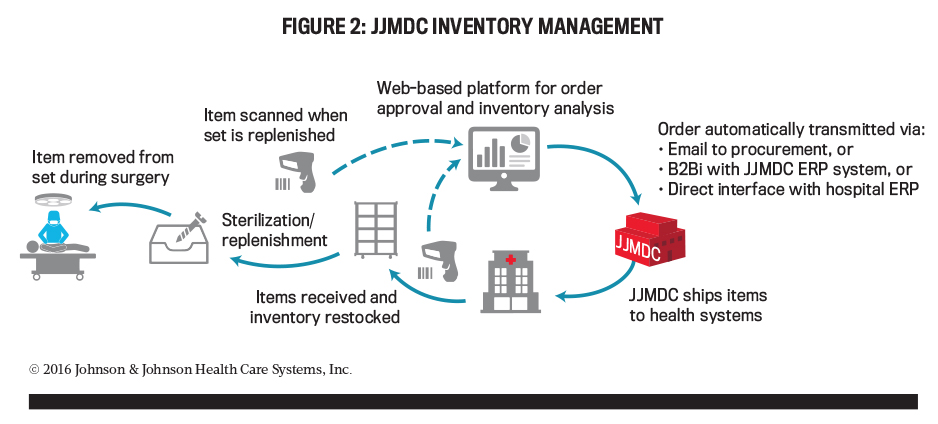

J&J’s Medical Devices business comprises a variety of platforms, one of which is orthopedics. Within the orthopedics area, J&J has launched a solution to support seamless inventory management for its customers. Ensuring a hospital has everything it needs for a procedure requires a significant amount of time to take inventory and then order what it expects it will need. It’s a manual process and, given the uncertainty of future needs, one that often results in waste due to slow-moving or expired products.

Conversely, a hospital could run out of something it needs if not planned correctly. But how do you make sure you are ordering everything you need when you aren’t sure what the future might hold? How can you integrate demand, technology, and ordering to make the entire process more seamless?

The J&J Medical Devices business has built a solution for this, called eSIMS Advanced Inventory Management Solutions (see Figure 2). It’s designed to aid in the ordering and management of products within the Johnson & Johnson Medical Devices Companies (JJMDC). The solution uses barcode-scanning technology to enable the solution.

Click to enlarge.

Click to enlarge.

With eSIMS, J&J provides a solution to a hospital that links into its enterprise resource planning (ERP) system and communicates securely and directly with the relevant JJMDC company in order to perform real-time procurement and analysis of stock. As a result, at any given moment the customer can see in real time the inventory level in stock, product turn rates, and where a product is stored.

What’s exciting about this example is that it isn’t only centered on the supply chain, but it connects back to efficient inventory management, purchasing, improving order accuracy, and reduced waste.

THE I4.0 BUSINESS CASE

But how do you build a business case to implement I4.0 in your organization? We need to adjust the mind-set a bit when it comes to I4.0. As finance and accounting professionals, we’re often valuing business cases or projects that can be identified in a single function or event. But I4.0 is broader and more connected, and we need to think about the value drivers across all functions to properly build a business case.

eSIMS offers proven value to hospitals in several ways. First, it reduces the amount of on-hand inventory a hospital needs, as it can buy the right product at the right time. Next, it reduces the number of orders placed as well as the cycle time. Lastly, it results in higher invoice accuracy. Overall, the customer benefits are simple and clear, and they make a difference in running a more efficient operation.

On the manufacturer side, J&J can gain several benefits. First, offering eSIMS as a solution creates a customer-centric approach. Additionally, from an inventory perspective, if the inventory is owned by J&J, turns and obsolescence can be optimized. From a cost consideration, you would want to incorporate the cost of investment to deliver the solution—both people costs and IT costs—into your business case. The net benefit is the value we can gain by implementation.

As you think about how to source data for building the business case, it’s important to think beyond data you might traditionally get out of a financial ERP system. Think about the benefit to the customer, and how you can measure those benefits, in order to truly capture the full value of the proposed business case.

Building a business case is exciting. Yet as finance and accounting leaders, we also should think about how we will enable our organizations to successfully adopt I4.0 principles as part of our daily lives. To become ingrained in the fabric of our organizations, we need to consider four key focus areas.

- Technical acumen and business expertise.We must be coaching our teams daily to ensure they truly understand the businesses they support and the value drivers. In the orthopedics case mentioned previously, it’s important for finance professionals to understand the end-to-end business model so that they can capture the value created across the supply chain.

- Technology enablers.There are many emerging solutions for finance and accounting professionals to leverage, such as Alteryx, Power BI, Tableau, and others. Regardless of the tool you decide to use, adding technology enables organizations to free up time to focus on customer insights. Unlocking those insights should add value for customers.

- Finance talent management.If you look around your organization, you might have started to see a new type of job opening in your departments, such as a data scientist role. This is because the skill sets these individuals have can add great value when complemented with “traditional” FP&A skill sets. As leaders, we should be actively supporting our staff as they seek out ways to grow in the area of Big Data management, technology, and the like.

- An external view.Make an active effort to look outside your own world to stay current. It sounds simple, but the complexity in many large organizations these days—the “matrix” so many of us must navigate—can create real barriers to gaining external perspectives.

Becoming best-in-class in these four areas will undoubtedly accelerate your journey in adopting I4.0 principles in your company, with finance and accounting driving the momentum. These areas align closely with several of the domains in the IMA Management Accounting Competency Framework.

That said, as with any journey into the unknown, there is no existing blueprint. J&J is taking an approach that goes from innovation to testing and then deployment. The journey requires reflection and adjustment in order to make sure goals are being met.

Companies on an intelligent I4.0 trajectory start with a value-based approach that first determines the sources of value, explores alternatives to capture that value, and then identifies enabling technologies. This might mean working within the current business model, but it also might mean a business model transformation, similar to what J&J is doing for orthopedic medical devices.

Finally, the scope of an I4.0 adoption can run a continuum that starts with a completely siloed focus. Silos are great places for the pilot studies, but without moving outside of functional boundaries, the potential benefits of I4.0 adoption are limited. As an example, a company might improve the manufacturing cycle time of a single product but not scale up the process to include other product lines or share the information with other divisions.

The next level is to confine the implementation to just within the four walls of the organization. Lessons learned from the silo-based pilot projects are used to scale up the implementation effort. Currently, many companies seem to restrict the focus to staying within the four walls. While this level of implementation offers greater potential benefits, it still falls short of capturing the greatest potential value.

In this new world, we see accelerated innovation and product cycles and enhanced customer power. Ignoring suppliers and customers during an I4.0 implementation limits the potential opportunities. The potential value of I4.0 goes beyond an organization’s results, and the greatest potential payoff comes from an end-to-end value chain I4.0 implementation effort. The key is focusing first on identifying ways to capture value, then finding the proper supporting technology and tracking metrics that monitor the points of intersection and promote cooperation within the supply chain.

There will be challenges along the way. Cross-functional cooperation is required to capture the full potential of I4.0, which, in turn, means that performance metrics may have to change in order to motivate that cooperation. This change requires top management support for partnering across functions and should probably include some measures of the direct benefits to the customers. This means looking beyond measures like on-time delivery, which is an internally focused measure of your own production and logistics, and let’s face it, shouldn’t customers simply expect on-time performance? We need to think about measures like the ones mentioned earlier—reduced surgical time and faster turnaround of the operating room between surgeries. These are direct customer benefits.

Of course, it isn’t enough for your systems to be fully integrated. You need to avoid the DRIP syndrome (being data rich and information poor). You need solid data services and analytics to turn the information being generated by your systems, sensors, and machinery into actionable insights that can provide a return on investment. Advanced analytics will become increasingly important. Also, remember the challenges that come with integrating data coming from different platforms and collection points, both within and from outside the organization.

I4.0 will become increasingly important to many, if not all, of us. This means we can’t stand still if we want to remain relevant and help our organizations thrive in this ever-changing environment. The agility that comes from increased connectivity facilitates just the kind of response to local, national, and global healthcare issues—tracking of availability of raw materials, the location of available production and testing capacity, and monitoring of distribution routes and delivery channels—needed in crises such as the COVID-19 pandemic we now face. As finance and accounting professionals, we must innovate, invest in the future, and transform ourselves to help manage the transitions that organizations will go through.

June 2020